Optical Plastic Color Sorter Working Principle

1.Plastic color sorter works based on the principle of optical sorting.

2.This is a process that involves the use of light to distinguish and sort different materials based on their properties.

3.The plastic optical sorter machine utilizes a source of light, such as an LED or laser, to illuminate a stream of plastic materials as they travel down a conveyor belt.

4.Sensors then detect the reflected light from the materials and send signals to the machine‘s computer system.

5.The signals are interpreted by the computer, which determines the color, shape, size, and transparency of each piece of plastic.

6.This information is then used to control jets of air nozzles, which shoot compressed air to divert the materials into appropriate bins.

7.This process results in the separation of different types of plastic materials, including PET, HDPE, PVC, and PP. Overall, the plastic optical sorter machine works by using advanced sensors and computer algorithms to detect and sort plastic materials based on their optical properties, thereby reducing the amount of waste and improving recycling rates.

Features

♦ High Precision sorting: The machine can accurately identify and sort different types of plastics based on their colors, shapes, and other physical properties, such as density, thickness, and transparency.

♦ High-speed sorting: A plastic optical sorting machine can be designed to sort a large volume of plastics within a short time, increasing production efficiency.

♦ Ease of use: The plastic optical sorting machine can have a user-friendly interface that allows operators to adjust settings and monitor the process.

♦ Flexibility: The plastic optical sorting machine can work with various plastic materials, including PET Flakes, PVC, HDPE, LDPE, and PP.

♦ Elimination of contaminants: The machine can remove other materials, such as metal, glass, and paper, mixed with the plastic waste.

♦ Minimal human intervention: The machine can work autonomously, minimizing the need for human intervention.

♦ Energy-efficient: The machine can be designed to consume minimal energy, reducing operation costs.

♦ Compact design: The plastic optical sorting machine can have a small footprint, saving space in the factory.

♦ Low maintenance: The machine can have a sturdy design and use durable components that require minimal maintenance.

♦ Cost-effectiveness: The plastic optical sorter machine can provide a cost-effective solution for plastic waste recycling, reducing waste disposal costs and generating revenue from reselling the sorted materials.

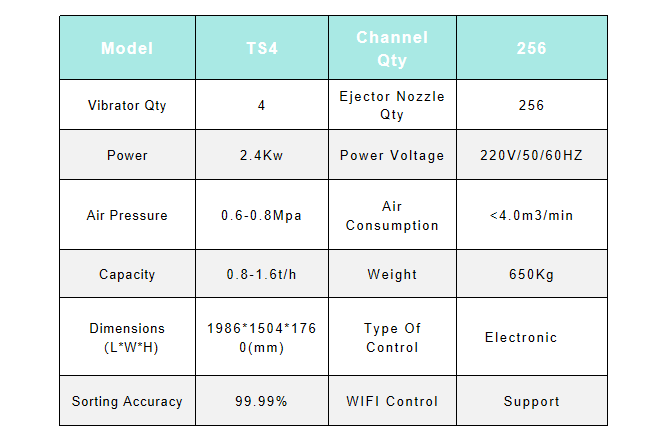

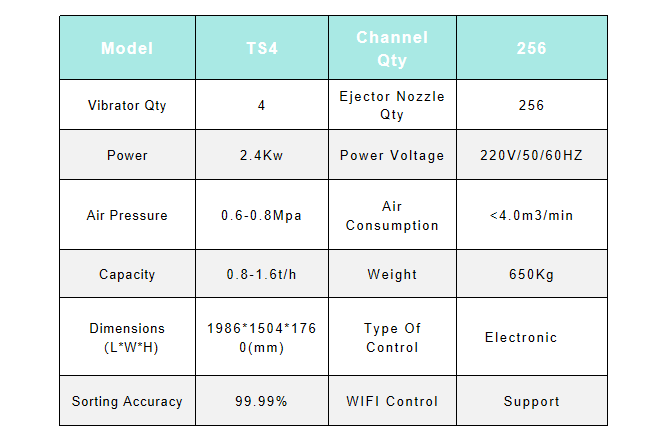

TS4 Plastic Optical Color Sorter Machine Technical Parameters

Superb Plastic Sorting Sulotions

Zdysort Plastic Color Sorter Core Advantages

Zdysort Color Sorter Project

Our Service

Pre-sale service

We will provide detailed solutions for your special requirement and help you know more about our color sorter.

After-Sale Service:Timely, efficient, customer first

1.Provide free training,consulting and technical support for users;

2.Provide personalized programs to the demands of customers;

3.Upgrade software for free for a life time;

4.Provide free warranty service for two years;

5.Provide 7*24 hours consultation and urgent service for users.

6.Follow status up time by time until the goods arrived.

www.topsortcolorsorter.com

Packing And Delivery

Packaging Details:

Our products use professional wooden cases with PE plastic bag.

Package size will depend on each model size.

Delivery Details:

Within 7-10 working days after received the 30% deposit.