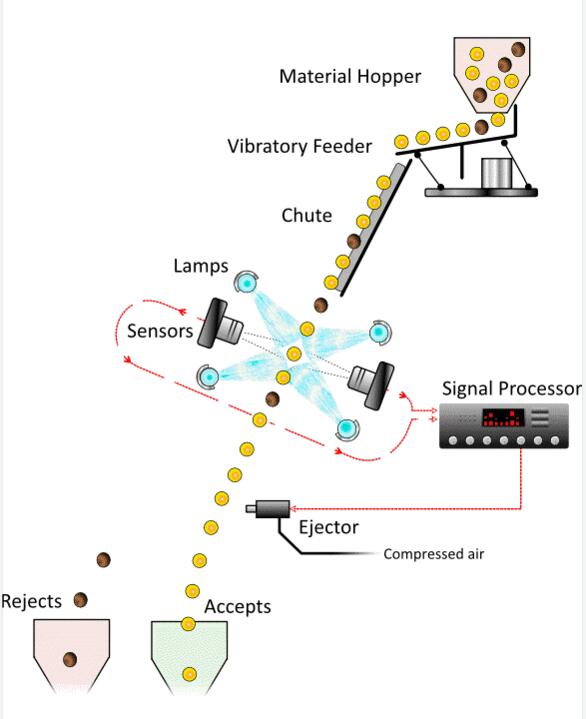

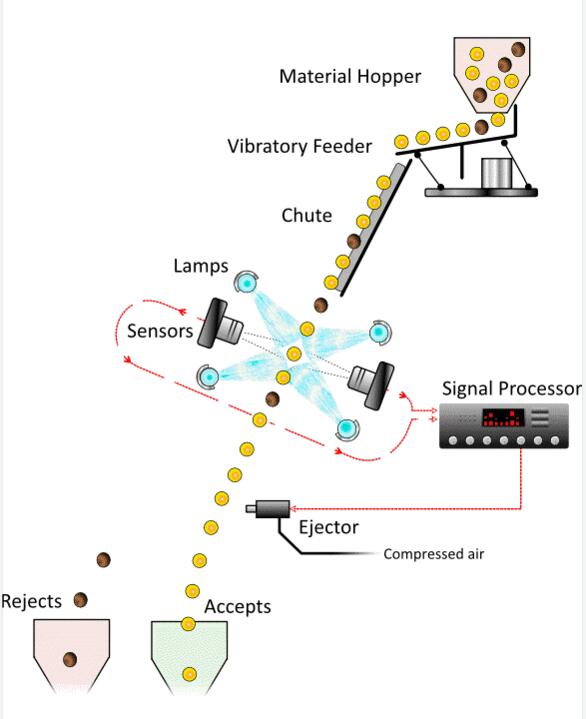

Color Sorting Machine Working Principle

Peanut color sorters use a combination of advanced digital imaging technology and powerful algorithms to identify and separate peanuts based on their color. The sorting process begins when the peanuts are fed into the machine. Inside, a high-resolution camera captures images of each peanut and sends them to a computer processor. The processor then analyzes the images and compares them to a pre-programmed database of colors. If the peanut is not within the acceptable range, it is identified as a defect and removed from the stream using an air jet. This process is repeated until all of the peanuts have been sorted according to their color.

3 chutes Peanut Color Sorting Machine Features

- High accuracy: The peanut color sorting machine is equipped with advanced image processing technology and high-precision optical components, which can accurately identify the color of peanuts and effectively remove the impurities.

- High efficiency: The peanut color sorting machine has a high sorting speed, which can reach 2000 kg/h, and can quickly sort out the qualified products.

- Easy to operate: The peanut color sorting machine adopts a touch screen operation interface, which is simple and convenient to operate, and can be easily mastered by workers with no experience.

- Low energy consumption: The peanut color sorting machine uses an air compressor as its power source, which has low energy consumption and is environmentally friendly.

3 Chutes Peanut Color Sorting Machine Technical Parameters

| Model |

R3-128 |

| Channles |

192 |

| Power |

1.9kw |

| Weight |

500kgs |

| Dimensions |

1650*1504*1760mm |

| Power voltage |

220V/50HZ/60HZ |

| Sorting accuracy |

99.99% |

| Capacity |

1500-2000kgs/h |

| Air consumption |

<3.0m3/min |

| Air pressure |

0.6-0.8Mpa |